- water makers (SeaRecovery)

- central vacuum cleaning systems (Beamvac)

- sanitary systems. (Jets)

- air conditioning (see below)

- security/fire detection

- power & battery management (Victron Energy, Asea Power, and more)

- communication/Internet

Converting a fishing trawler into a private exploration vessel and diving liveaboard.

Several reasons. As John deCaro states on his very informative website BuyExploreryachts.com:

Several reasons. As John deCaro states on his very informative website BuyExploreryachts.com:

Right now, we can carry 126 tons -just over 33 thousand gallons - of diesel oil.

Right now, we can carry 126 tons -just over 33 thousand gallons - of diesel oil.

Jan Klumpenaar at Victron Energy, makers of the very versatle MultiPlus system, thanks for answering my many e-mails and helping me find my way to Asea Power frequency converters, helping me save lots of $$ so I can still built a power system that we want.

Jan Klumpenaar at Victron Energy, makers of the very versatle MultiPlus system, thanks for answering my many e-mails and helping me find my way to Asea Power frequency converters, helping me save lots of $$ so I can still built a power system that we want.

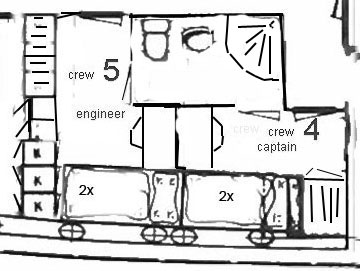

In the rear of the vessel, we'll create a small stateroom for the captain and engineer. They will share a bathroom. This way, they'll be very close to both bridge and engineroom. Of course, they will be able to monitor their relevant systems from their stateroom.

In the rear of the vessel, we'll create a small stateroom for the captain and engineer. They will share a bathroom. This way, they'll be very close to both bridge and engineroom. Of course, they will be able to monitor their relevant systems from their stateroom.

Below these staterooms there's still standing room (well, almost) and space for supplies and equipment like laundry and maybe some spare berths for crew. Or kids. Access will be from the main deck through the area indicated as 'naar onderruim'.

Below these staterooms there's still standing room (well, almost) and space for supplies and equipment like laundry and maybe some spare berths for crew. Or kids. Access will be from the main deck through the area indicated as 'naar onderruim'.

Our Bauer rep. in The Netherlands is CST Schiphorst. Harry Schiphorst gave us some really good advice on equipment selection and setup saving us big $$. So, the business is his.

Our Bauer rep. in The Netherlands is CST Schiphorst. Harry Schiphorst gave us some really good advice on equipment selection and setup saving us big $$. So, the business is his.